Valves & Accessories

As an industrial valve supplier, API UK stocks a wide selection of high-quality and reliable industrial and process control valves. Constructed from lightweight aluminium, our industrial valves feature hard anodised aluminium spools to ensure long service life.

Industrial Process and Control Valves

At API UK, we have an extensive range of high-quality industrial valves to suit a multitude of applications. With various sizes available, our industrial valves and pneumatic accessories can be tailored to suit your precise application requirements. As leading control valve manufacturers, we can provide everything from ISO control valves to solenoid and pneumatic valves. In addition, we can also provide a variety of ATEX versions of our industrial valves for use within hazardous environments.

All of our process control valves are constructed with a focus on long-service and high-quality performance in mind for our customers. Additionally, all API valves are delivered pre-lubricated as standard, ensuring compatibility with dry and lubricated compressed air systems.

Our complete list of pneumatic tools and accessories includes the following:

- Stainless Steel Valves

- ISO Control Valves

- Solenoid Valves

- Pneumatic Valves

- Manual and Mechanical Valves

- Actuated Ball Valves

- Ancillary Valves

- Pneumatic Valve Accessories

Stainless Steel Valves

API UK is one of the few manufacturers that can provide industrial and process industries with heavy-duty, stainless steel valves. Manufactured from AISI 316L stainless steel, our valves offer the highest grade of stainless steel to meet demanding application requirements, such as those within the pharmaceutical, food and beverage, marine and oil, and gas industries.

Our stainless steel valve range is made up of control valves, spool valves and ancillary valves. In addition, we can also provide ATEX standard stainless steel valves for use within areas with a high explosive risk. For additional customisation, we can also provide FFKM seals for use in high-temperature environments upon request.

ISO Control Valves

Our collection of ISO control valves is manufactured from die-cast painted and hard anodised aluminium spools. Conforming to ISO 5599/1 standards, API’s ISO spool valves are reliable lightweight control valves that are capable of delivering long service life for any application.

As trusted control valve manufacturers, meeting ISO 5599/1 standards is crucial to ensure our ISO control valves are interchangeable with any valve that’s manufactured to this specification. Our ISO control valves are available in both electrically-operated and pneumatically-operated versions, depending on your application requirements.

Solenoid Valves

Solenoid valves from API UK are available in a variety of options to suit a wide range of process requirements. Our solenoid valve selection includes A1 and A2 series solenoid valves which are solenoid and electrically operated, respectively, for use in applications that deal with compressed filtered air. Meanwhile, our range of directly operated and indirectly operated solenoid valves are used in water and steam applications.

Pneumatic Valves

Our range of pneumatic valves are as diverse as any product within our valve range. You can choose from our A1 series pneumatic spool valves with the option for either panel or sub-base mounting for high-flow applications. Alternatively, our ISO 5599/1 conforming pneumatic valves are designed for use with compressed air, with or without lubrication.

Manual and Mechanical Valves

Manual and mechanical valves from API UK are designed to provide the widest range of operating options available on the market. We have a number of manual and mechanically-operated pneumatic valves to suit whatever your application’s requirements are. From wide or roller levers to top-level and push-pull, API manual and mechanical valves are manufactured with customer satisfaction in mind.

Actuated Ball Valves

The actuated ball valves in our range are customisable to match the requirements of our customers. We have an extensive selection of pneumatic actuated ball valves available to purchase online. Our actuated ball valves can be manufactured from hardened or anodised aluminium as well as brass and stainless steel on request. We can also provide single, double-acting or ATEX-actuated ball valves depending on your process needs.

Ancillary Valves

Our range of ancillary valves are the final featured product of our valve range. Our high-quality ancillary valves can provide your business with a reliable and cost-effective hydraulic solution. Whether you require safety, slide valves or uni-directional valves, we have a comprehensive selection of ancillary valves to choose from.

Valve Accessories

To complement our valve range, we also supply a variety of pneumatic accessories. As leading suppliers of high-quality valve accessories, we can supply your business with a variety of coils and connectors that are designed to work in tandem with any specific corresponding valve type.

All of our valves will accept any coil voltage, which eliminates the need to buy full valve and coil sets, enabling you to make cost savings. In addition, we can also provide valve mounting plates, either with the NAMUR interface or plates with A1 series valve compatibility.

If you would like to find out more about our pneumatic tools and accessories range, don’t hesitate to contact us today.

Frequently Asked Questions about Pneumatic Tools, Valves and Accessories

What are the key considerations when selecting a pneumatic valve for highly dynamic applications?

In high-speed and dynamic applications, valve selection is critical. Considerations include response time, flow rates, and durability. Look for valves with low internal friction and minimal dead volume to ensure rapid response and precise control. Additionally, explore valve designs that can handle frequent cycling without compromising performance or lifespan. Advanced solenoid valves with efficient magnetic circuits and optimised armature designs are often preferred for such demanding applications.

What strategies and components are recommended for achieving optimal pneumatic energy efficiency in large-scale systems?

Optimising energy efficiency in extensive pneumatic systems requires a holistic approach. Consider incorporating strategies like pressure regulation, air leakage management, and demand-based control. Utilising pressure sensors, flow meters, and advanced controllers can enable real-time monitoring and adjustment of system parameters. Integration of smart valve manifolds with predictive maintenance capabilities can minimise downtime and improve system reliability. Furthermore, exploring innovative valve designs that minimise air consumption during valve actuation can significantly contribute to energy savings in high-volume operations.

What maintenance is required for pneumatic tools and accessories?

Regular maintenance is essential for prolonging the lifespan and performance of pneumatic accessories. This includes lubricating the tools with the appropriate oil to prevent wear, cleaning internal components to remove debris, inspecting hoses and connectors for damage, and periodically checking air pressure regulators and filters to ensure consistent airflow quality.

How often should I lubricate my pneumatic tools?

The frequency of lubrication depends on the tool’s usage and the manufacturer’s recommendations. Some tools require lubrication before every use, while others might need it less frequently.

-

Manual & Mechanical Valves

API Pneumatic UK supplies an extensive range of manual & mechanical valves. These pneumatic valves can be used as pilot or power valves. This includes foot operated, push-pull, lever valves and many more. -

Coils & Connectors

API Pneumatic UK’s coil and connectors are available in a variety of types, specific to your requirements. We also have ATEX versions available in both coils and connectors, for extra reliability and durability in hazardous or potentially explosive environments.

downloads

what’s happening in the world of pneumatics?

-

The Role of Pneumatics in the Pharmaceutical Industry

The pharmaceutical industry is one of the most vital sectors in today’s modern world and is instrumental in improving and maintaining public health. A significant aspect of the pharmaceutical industry is its ability to ensure the quality, efficiency, and safety of pharmaceutical processes to protect human health and life. To achieve this, an array of … Continue reading The Role of Pneumatics in the Pharmaceutical Industry

-

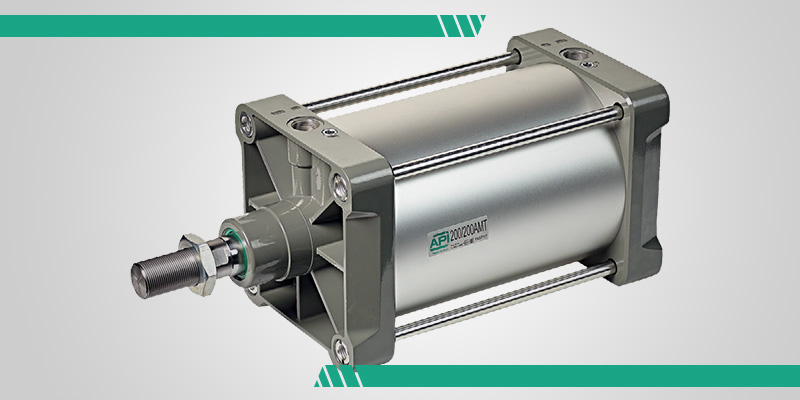

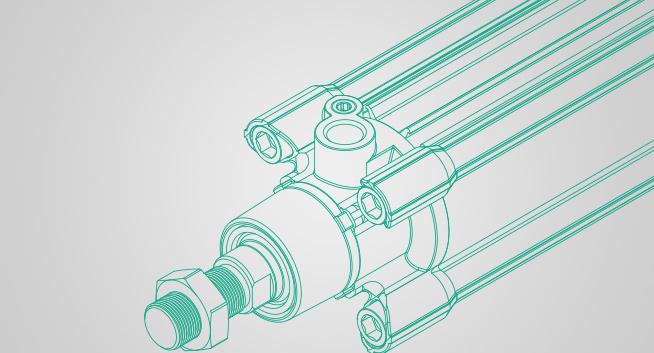

Understanding the different types of Pneumatic Cylinders

Pneumatic cylinders are mechanical devices that are used to compress air to produce rotary or linear motion and are essential components in a wide range of industrial applications. When the device compresses air, the energy converted goes into mechanical work. One of the reasons why they’re so commonly used in various industries is because they’re … Continue reading Understanding the different types of Pneumatic Cylinders

-

How to build a pneumatic system

Pneumatic systems are a reliable and efficient means of power transmission that play a crucial role in various industries. They can harness the power of compressed air and are often used for purposes such as control, automation and actuation. Here at API Pneumatic UK, we are a leading supplier of air treatment products and equipment … Continue reading How to build a pneumatic system